We are always available for information!

Contact us by email @info@gpeitalia.com or at +39 0521.883345.GPE | Services

GPE | By Design

Design

From the initial request to the most complex technical drawing, every detail is carefully engineered to ensure high performance and long-term reliability.

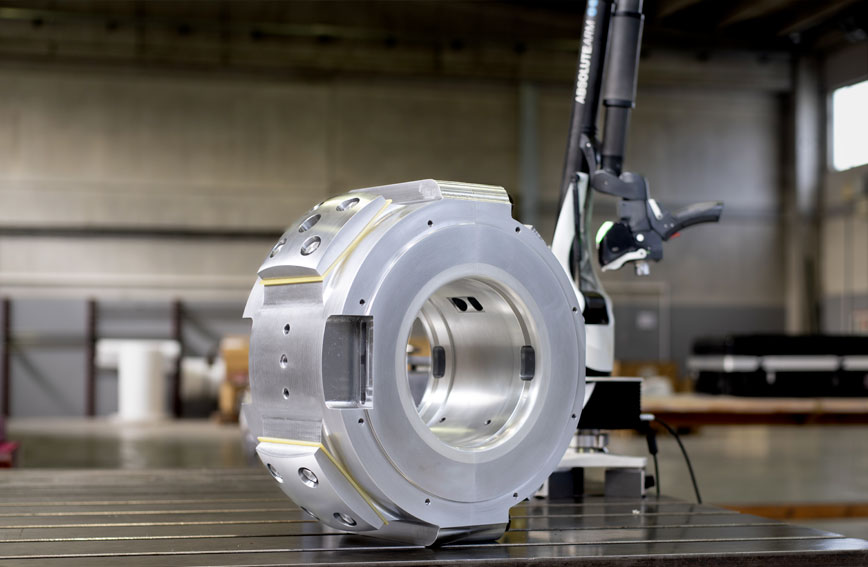

Reverse Engineer

Starting from the existing component, we develop a complete CAD model to digitally reconstruct the part, analyze its geometry, and regenerate mechanical elements with precision and consistency.

Quality control

Product and material testing is an integral part of our process. Precision is just the starting point: each component is thoroughly inspected to ensure real-world functionality, consistent performance, and long-term reliability.

Traceability

Every component is tracked and documented throughout the entire production cycle—from material intake to final delivery—ensuring certified quality, full traceability, and operational safety

GPE | General Project Energy

Specializing in the production, maintenance, and supply of components and services, we are a leading partner for the Energy, Oil & Gas, and Industrial Plant sectors.

Our dedication to quality is reflected in our UNI EN ISO 9001:2015 certification, which guides us in managing every process, both internal and external, and in the selection of our partners. As a testament to our growth and vision, we have inaugurated a new headquarters spanning over 10,000 square meters, a modern and functional facility to support our most ambitious projects.

GPE | General Project Energy

Our goal is to offer our clients expertise and professionalism. We are your guarantee of success.

Overhaul.

Overhaul of In-Service Components

Component overhaul requires specialized expertise and a deep understanding of industrial applications. Our experienced team approaches each intervention with targeted solutions tailored to the specific needs of the project. Every phase is managed with precision to ensure that the regenerated component meets operational requirements and is ready for a new production cycle.

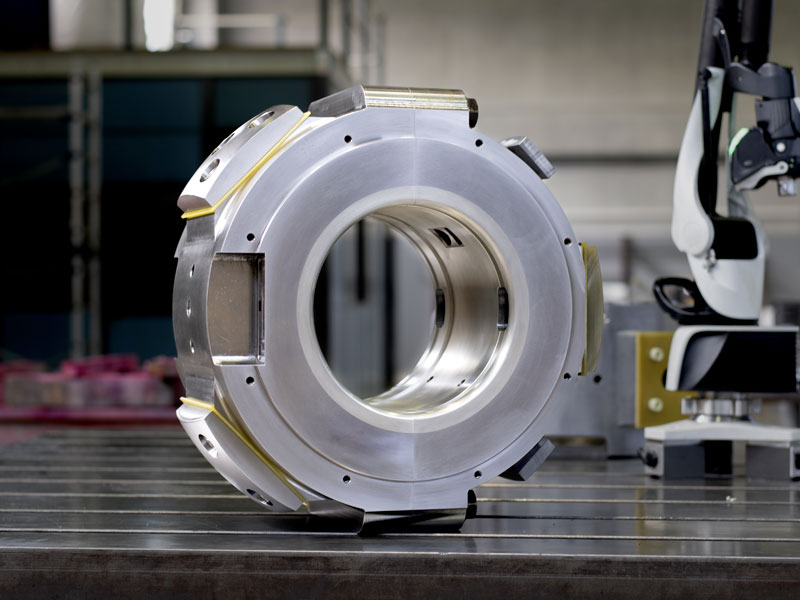

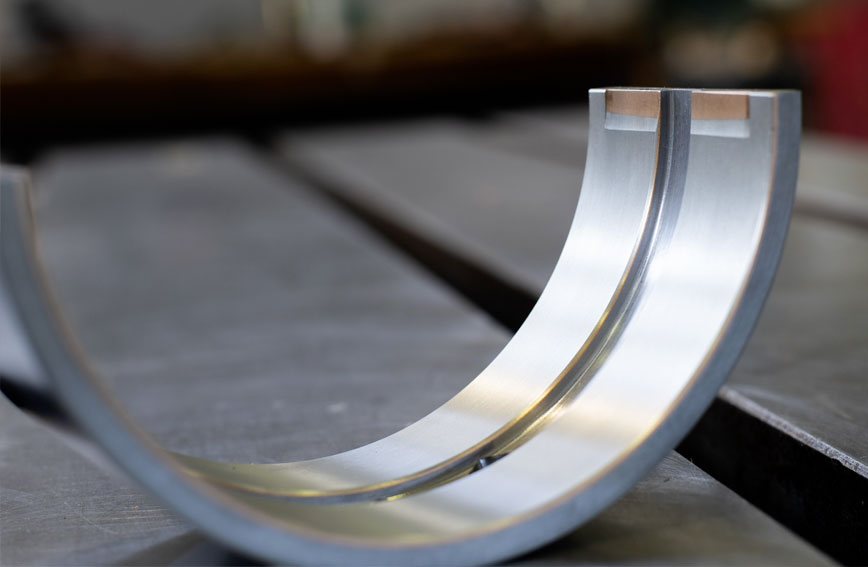

Overlay Technologies

Anti-Friction Overlay Technologies

At the core of our production process, the application of antifriction alloys on oil-film sliding bearings is a distinctive expertise, developed and refined through years of experience in the mechanical engineering sector. Our company is equipped to apply all lead-free white metal alloys, in full compliance with environmental regulations and the technical specifications required by major rotating machinery manufacturers.

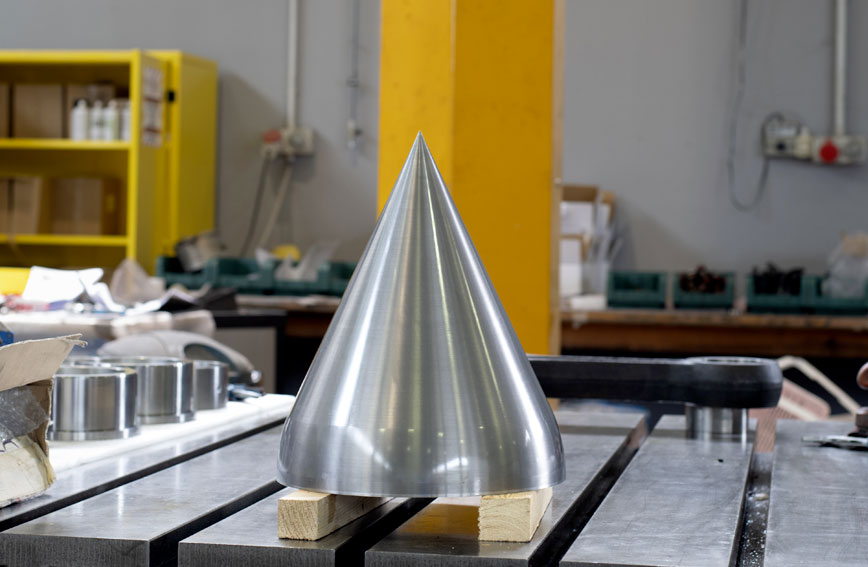

New components

We supply new mechanical components

based on customer documentation, drawings, and technical specifications. Each part is manufactured with careful attention to materials, geometry, and operating conditions to ensure high performance and long-term reliability. Our flexible production process allows us to meet a wide range of application needs, delivering tailored solutions for industrial plants and rotating machinery.

Quality control

Quality control is a key phase of our production process

Inspections are carried out by multi-sector Level 2 NDT certified personnel in accordance with UNI EN ISO 9712, with expertise in the main non-destructive testing methods: penetrant testing (PT), ultrasonic testing (UT), magnetic particle testing (MT), and visual testing (VT). Checks are performed during the main production stages, taking into account the customer’s technical specifications to ensure dimensional and functional compliance of each component.

Mechanical machining

GPE provides complete mechanical machining services

Turning, boring, and grinding for small, medium, and large components. Our high-precision operations are suitable for complex geometries and a wide range of metal alloys, including alloyed and high-performance steels, ensuring reliable results that meet technical specifications. The service is designed to meet the needs of various industrial sectors, with flexibility and attention to detail..

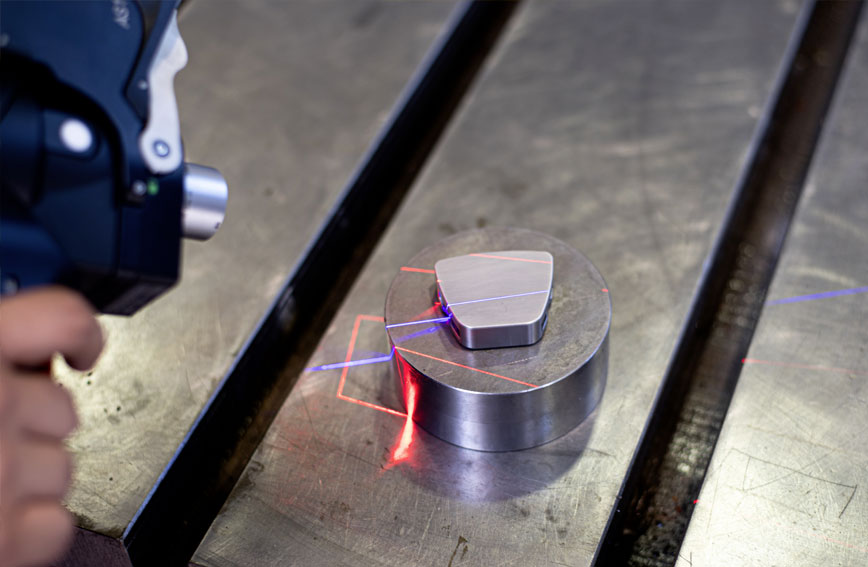

Reverse engineering

Reverse engineering is one of our core competencies

enabling us to restore mechanical components even when technical documentation is incomplete. We rely on advanced 3D laser scanning technology to accurately capture the part's geometry, even when original drawings are unclear or partially degraded. This digital process allows us to reconstruct the CAD model, analyze every detail, and develop functional, reliable solutions.