We are always available for information!

Contact us by email @info@gpeitalia.com or at +39 0521.883345.Anti-Friction Overlay Technologies

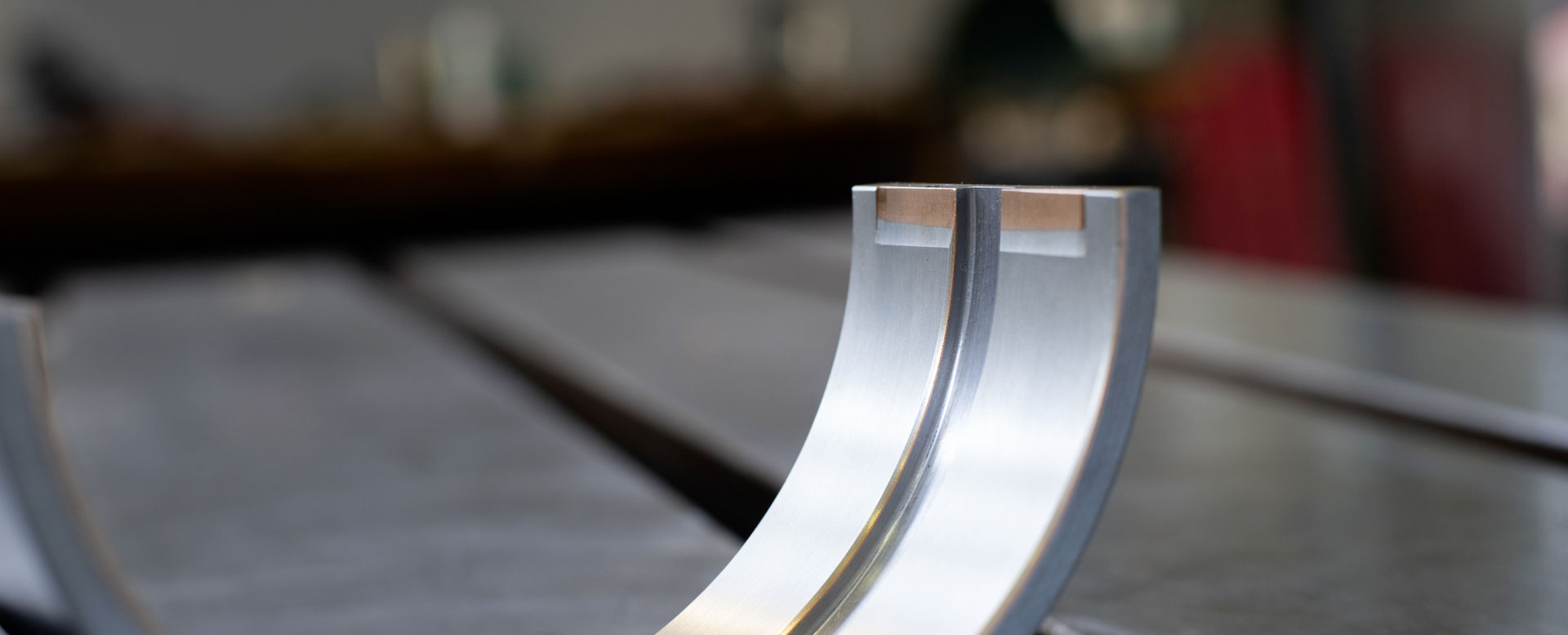

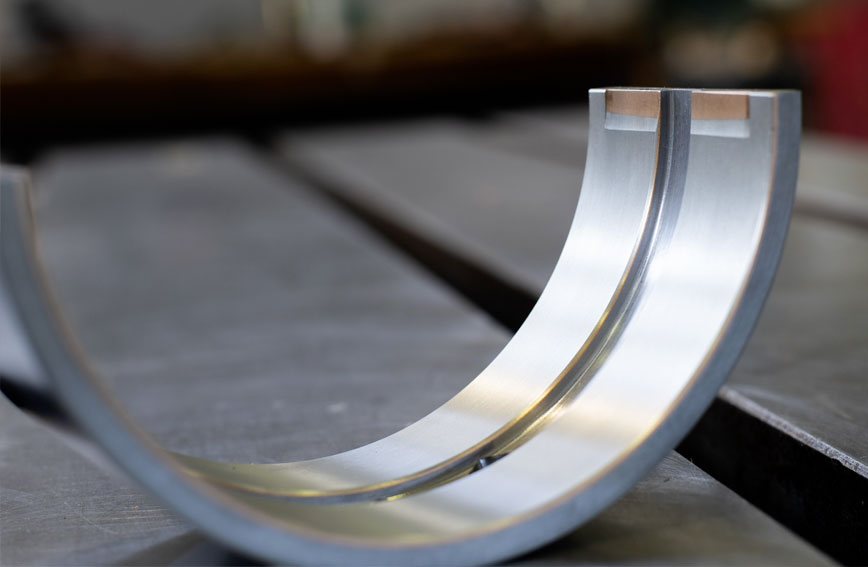

At the core of our production process, the application of antifriction alloys on oil-film sliding bearings is a distinctive expertise, developed and refined through years of experience in the mechanical engineering sector. Our company is equipped to apply all lead-free white metal alloys, in full compliance with environmental regulations and the technical specifications required by major rotating machinery manufacturers.

To ensure maximum precision and repeatability, we operate a dedicated machine fleet for overlay application, designed to handle complex geometries and tight tolerances. Our equipment allows for accurate control of thermal and mechanical parameters during the melting and solidification phases, ensuring optimal adhesion between the substrate and the deposited alloy.

Each machine is configured to work on components of various sizes and materials, with advanced handling and positioning systems that adapt the process to the specific features of each job. Operational flexibility, combined with the expertise of our technical staff, enables us to manage even the most demanding applications while maintaining high quality and productivity standards.

Specialized equipment for anti-friction metal coating processes

- Max melting furnace capacity: 1000 kg

- Rotation Ø: 20 to 2200 mm

- Max weight: 6000 kg

- n°1 Centrifuge «Brons 300»

Max speed 1500 rpm/min – Max weight on flange 300 Kg. - n°1 Centrifuge «Brons 400»

Max speed 1200 rpm/min – Max weight on flange 400 Kg. - n°1 Centrifuge «Brons 1500»

Max speed 750 rpm/min – Max weight on flange 1500 Kg – Max rotation diameter 1400 mm.

- n°1 Centrifugal Casting plant 4.0 - GPE 2200

Max melting furnace capacity 1000 Kg - Max speed 420 rpm/min

Max weight on flange 6000 Kg - Max rotation diameter 2200 mm. - Gravity casting station dimensions 4 x 6 metres.

- Brazing process and White Metal coating with drop by drop welding technique.

- Brazing process and White Metal coating with TIG/GTAW welding technique.

- Application of pink metal coating for trimetallic bearing assemblies